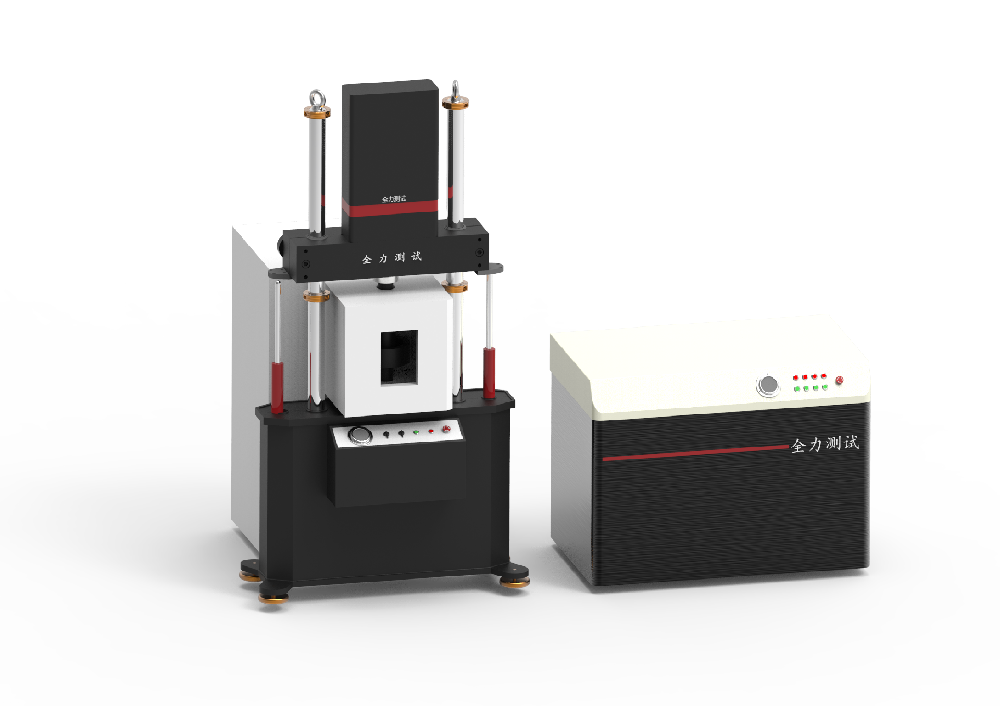

液压万能试验机在建筑装饰材料、金属复合材料的结构力学检测处起着关键的功效。其可以精确的所必须的测试数据,因此液压机拉伸试验机在大中型钢铁行业及其质量检验企业试验室中获得了普遍应用。可是在液压机拉伸试验机的应用全过程中,人们理应留意对其的维护保养和维护保养。许多实验工作人员针对液压机拉伸试验机应用中出現的常见故障,常常埋怨。我觉得许多难题都由于实验工作人员针对液压机拉伸试验机应用全过程中不留意其恰当的方法,可能会导致试验仪出現难题。假如对液压机拉伸试验机有充足的了解,则人们就能够非常好地防止事儿的产生。那麼,怎样保证液压机拉伸试验机的恰当维护保养及其该机器设备的校零常见问题你掌握吗

Hydraulic universal testing machine plays a key role in structural mechanics testing of building decorative materials and metal composite materials. It can accurately test the necessary data, so the hydraulic press tension testing machine has been widely used in large and medium-sized steel industry and its quality inspection enterprise laboratories. However, in the whole process of application of Hydraulic Press Tension Testing machine, people should pay attention to its maintenance and maintenance. Many experimenters often complain about the common faults in the application of Hydraulic Press Tension Testing machine. I think many difficulties are due to the fact that the experimenters do not pay attention to the proper methods during the whole process of the application of the hydraulic press tension testing machine, which may lead to the difficulties of the tester. If we know enough about the hydraulic press tension testing machine, people can prevent things from happening very well. Then, how to ensure the proper maintenance of the hydraulic press tension testing machine and the common problems of zero-calibration of the machine and equipment?

怎样保证液压机拉伸试验机的恰当维护保养及其该机器设备的校零常见问题

How to ensure the proper maintenance of the hydraulic press tension testing machine and the common problems of zero calibration of the machine and equipment

一、如何做到液压万能试验机的正确维护

How to Maintain the Hydraulic Universal Testing Machine Correctly

用合适的夹具完成相应的实验。液压万能试验机只配有标准试样的夹具,而对于非标准的式样就需要用合适的夹具来配合其使用,以保证试验的精确性。

Complete the corresponding experiment with the appropriate fixture. Hydraulic universal testing machine is only equipped with fixtures for standard samples, and for non-standard patterns, it is necessary to use appropriate fixtures to cooperate with its use in order to ensure the accuracy of the test.

液压万能试验机的清扫与清洁工作。试验过程中不可避免的会出现一些粉尘。这些粉尘如果得到不到及时的清理,就有可能给液压望能试验机带来重大的损害,所以每次使用后就必须进行清扫工作。

Cleaning and cleaning of hydraulic universal testing machine. Some dust will inevitably appear during the test. If these dust can not be cleaned up in time, it may cause great damage to the hydraulic energy expectancy testing machine, so it must be cleaned after each use.

及时补充液压油。液压油是要在一定时期进行补充的。

Replenish hydraulic oil in time. Hydraulic oil should be supplemented in a certain period of time.

过滤器的更换。一般来说对于带堵塞指示器的过滤器要及时检测更换,而不带堵塞指示器的液压万能试验机应当每六个月换一次。

Replacement of filters. Generally speaking, the filter with blocking indicator should be detected and replaced in time, and the hydraulic universal testing machine without blocking indicator should be replaced every six months.

定期检查元器件。

Check components regularly.

紧固件要定期进行锁紧。试验的过程可能带来紧固件的松动,因而要定期对其进行处理。

Fasteners should be locked regularly. The process of test may bring about loosening of fasteners, so it should be treated regularly.

冷却器的清理和检查。定期观察冷却器情况,如果有积垢,要及时清理。

Cleaning and inspection of cooler. Regular observation of the cooler, if there is fouling, to clean up in time.

蓄能器的补充问题。如果蓄能器中的压力不够,就及时的补充。

Supplementary problems of accumulator. If the pressure in accumulator is not enough, it should be supplemented in time.

传动部分及时进行涂抹润滑剂。这样能够减少摩擦。

The transmission part is coated with lubricant in time. This reduces friction.

如何做到液压万能试验机的正确维护以及该设备的调零注意事项

How to Maintain the Hydraulic Universal Testing Machine Correctly and Notices for Zero Adjustment of the Equipment

二、液压万能试验机调零的注意事项

II. Notices for Zero Adjustment of Hydraulic Universal Testing Machine

零点过大时,先调节零点,然后在各档位分别对软件清零

When the zero is too large, first adjust the zero, then clear the software in each gear.

油缸未升起时,试验力显示负值,属于正常现象,请不要调整零点

When the cylinder is not raised, the test force shows a negative value, which is a normal phenomenon. Please do not adjust the zero point.

对于零点的调整,应在引伸计在试样上装夹完毕后,且试验活塞处于静止状态时进行

For the adjustment of zero point, it should be done after the extensometer is clamped on the sample and the test piston is in a static state.

液压万能试验机一般情况下,调速人员已将传感器的零点调整好,每次启动时,系统会自动校准启动零点,无需用户再调整

Generally speaking, the governor has adjusted the zero of the sensor well. When the system starts up, the zero of the sensor will be automatically calibrated without any readjustment by the user.

用户可以用硬件调零按钮调整硬件零点,系统会自动记录新的零点调整值

Users can adjust the hardware zeros with the hardware zeros button, and the system will automatically record the new zeros.

不分档测量没有调节零点,因此对于液压万能试验机来说,因为是全程不分档,因此该事项适用于电子万能试验机。

Non-grading measurement does not adjust zero point, so for hydraulic universal testing machine, because the whole process is non-grading, so this matter applies to electronic universal testing machine. http://www.quanlitest.com/