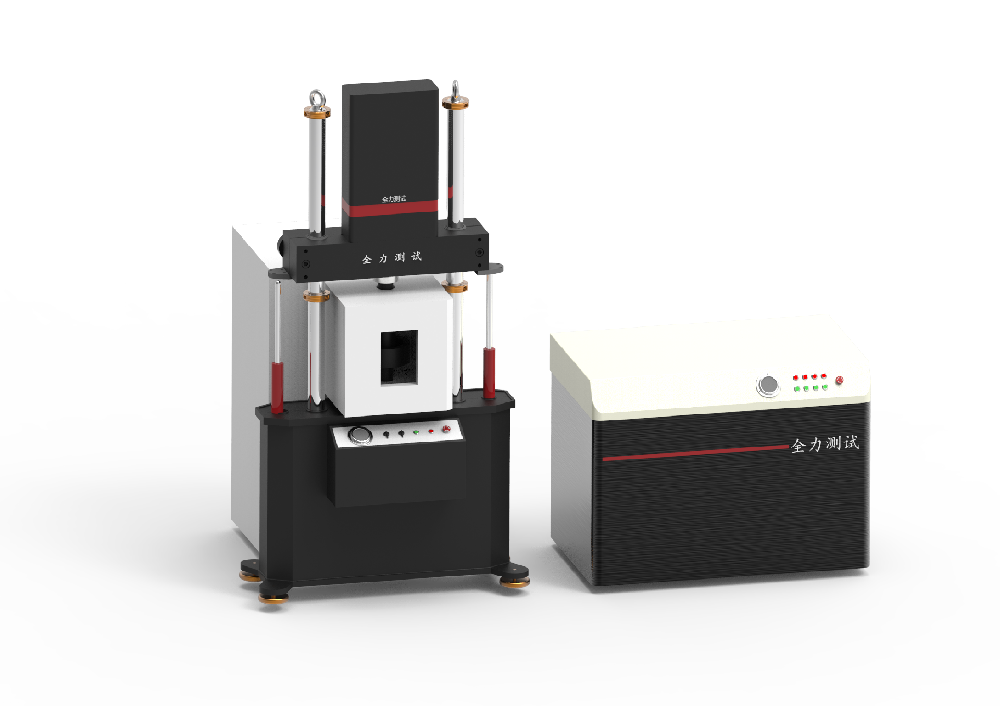

电子万能试验机:万能材料试验机也叫万能拉力机或电子拉力机。 单独的伺服电机载入系统软件,高精宽频液压伺服阀,保证系统软件精密高效率、低噪声、迅速没有响应;选用单独的液压机夹持系统软件,保证系统软件低噪声稳定运作,

Universal material testing machine is also called universal tension machine or electronic tension machine. Separate servo motor loads system software, high precision and wide frequency hydraulic servo valve, which ensures that the system software is precise, high efficiency, low noise, fast and no response; Select separate hydraulic press clamping system software to ensure that the system software operates stably with low noise.

一、万能材料试验机的主机构成

I. The Main Engine Composition of Universal Material Testing Machine

万能材料试验机关键由支撑架、液压机操纵箱、表面测力呈现、电路系统构成。其人体一些有考量,立杆、上下左右抗压强度机器设备,发动机缸体,声卡机架、底版等。测量表面安裝在声卡机架右边上端。液压操作有些安装在万能资料试验机机架右侧的下部,下抗折设备装在活塞顶部,两边装有导向板,能坚持抗折台面上下运动方位不变。抗折台表面配有尺标,2个限两侧配有导向性板,可随意调养抗压强度跨度,拖锟能上下左右主题活动,使支承时要具有均衡实际效果,在考量下配有上抗折机器设备,经过掉头螺栓两根定位柱固定在横梁下,其间有球头、球座,螺栓上装有绷簧以便平衡上抗折设备,拖锟能上下活动。

The key of universal material testing machine is composed of support frame, hydraulic press control box, surface force measurement presentation and circuit system. Its human body has some considerations, such as vertical pole, upper and lower left and right compressive strength machine equipment, engine block, sound card rack, bottom plate, etc. The measuring surface is mounted on the upper right side of the sound card rack. Some hydraulic operations are installed at the lower part of the right side of the frame of universal data testing machine, and the lower anti-bending equipment is installed at the top of the piston, with guide plates on both sides, which can keep the movement orientation of the anti-bending table unchanged. The surface of the folding table is equipped with a ruler, two limited sides are equipped with a guide plate, which can adjust the compressive strength span at will, and the dragging bracket can move up and down on the left and right themes, so as to achieve a balanced practical effect when supporting. Under consideration, the folding table is equipped with an upper bending machine equipment. After turning bolts, two positioning posts are fixed under the cross beam, with a ball head and a ball seat between them. The bolt is equipped with a tension spring to balance the bending resistance equipment and the towing bracket can move up and down.

抗折台表层装有尺标,2个限两边装有主导性板,可随便调理抗拉强度跨距,拖锟能前后左右活动主题,使支撑板时要具备平衡预期效果,在考虑下装有上抗折机械设备,烟尘进到活塞杆与液压缸间,进而二者加速损坏。抗压强度实验时,要是在抗压强度橱柜台面管理中心,放入抗压强度保护层垫块及下弯排机,在承重梁下拆下来抗压强度机器设备,就能开展抗压强度实验活塞杆与液压缸间下设密封环,可防止液压油外流,在缸顶开有一环形槽,并有漏油通道,经过塑料管,把油溢流回油箱。

The folding table is equipped with a ruler on the surface and a dominant plate on both sides of the two limits. It can adjust the span of the tensile strength at will. The drag can move around and around, so that the supporting plate should have the desired balance effect. The bending resistant mechanical equipment should be installed under consideration. The smoke and dust enter between the piston rod and the hydraulic cylinder, thus accelerating the damage of both. In the compressive strength test, if the cushion block and the bending machine are put in the counter management center of the cabinet, and the compressive strength machine and equipment are removed under the load-bearing beam, the sealing ring between the piston rod and the hydraulic cylinder can be carried out, which can prevent the hydraulic oil from flowing out and has a ring shape at the top of the cylinder. The groove has an oil leak passage, and the oil spills back to the tank through the plastic pipe.

二、万能材料试验机的主机规格

II. Host Specification of Universal Material Testing Machine

主机规格: A.高精度力量传感器: 0~10KN 20ton。力量精度在±0.5 以内。 B.容量分段:全程七档:× 1,× 2,× 5,× 10,× 20,× 50,× 100%.全程力量最大解析度 1/1000,00 C.动力系统:台湾变频器+交流变频电机+蜗轮蜗杆减速机+T型丝杆。 D.控制系统: 采用Pulse Command控制方式使控制更精准,速度控制范围5~250 mm/min。具有快速粗调与慢速微调功能。测试后自动回归原点、自动储存。 E.数据传输方式:RS232传输 F.显示方式:UTM107+WIN-XP测试软件液晶屏显示。 G.简洁的全程一档与精密全程七档力量线性双校正系统。 H.豪华测试界面软件可实现定速度、定位移、定荷重控制模式加上多阶控制模式可满足普通的测试要求。I.测试空间:测试宽度约400 mm(标准规格)行走空间800 mm(不含夹具)(标准规格) J.全程位移: 编码器1800 P/R,提升4倍精度,采用LINE DRIVE编码器抗干扰能力极强位移解析0.001mm。小变形:金属引伸计,解析 0.001mm(选配) K.安全装置:过载紧急停机装置、上下行程限定装置、漏电自动断电系统、自动断点停机功能。 M.手控方式:可增添手动操作盒。

Host specification: A. high precision force sensor: 0 ~ 10kN 20ton. The force accuracy is within (+0.5). B. Capacity Segmentation: Seven gears in the whole process: *1,*2,*5,*10,*20,*50,*100%. Maximum resolution of the whole process force is 1/1000,00 C. Power system: Taiwan frequency converter+AC frequency converter+worm reducer+T-type screw. D. Control system: Pulse Command control mode is adopted to make the control more precise, and the speed control range is 5-250 mm/min. It has the functions of fast coarse tuning and slow fine tuning. Automatically return to the origin and store after testing. E. Data transmission mode: RS232 transmission F. Display mode: UTM107 + WIN-XP test software LCD display. G. Simple linear double calibration system with one gear and seven gears. H. Deluxe test interface software can achieve constant speed, positioning, fixed load control mode and multi-level control mode to meet the common test requirements. I. Test space: Test width is about 400 mm (standard specification) Walking space is 800 mm (without fixture) (standard specification) J. Full-range displacement: encoder 1800 P/R, improve 4 times accuracy, using LINE DRIVE encoder anti-interference ability very strong displacement analysis 0.001 mm. Small deformation: Metal extensometer, 0.001 mm (optional) K. Safety device: overload emergency stop device, upper and lower travel limit device, leakage automatic power cut system, automatic breakpoint stop function. M. Manual control mode: Manual operation box can be added.

http://www.quanlitest.com/