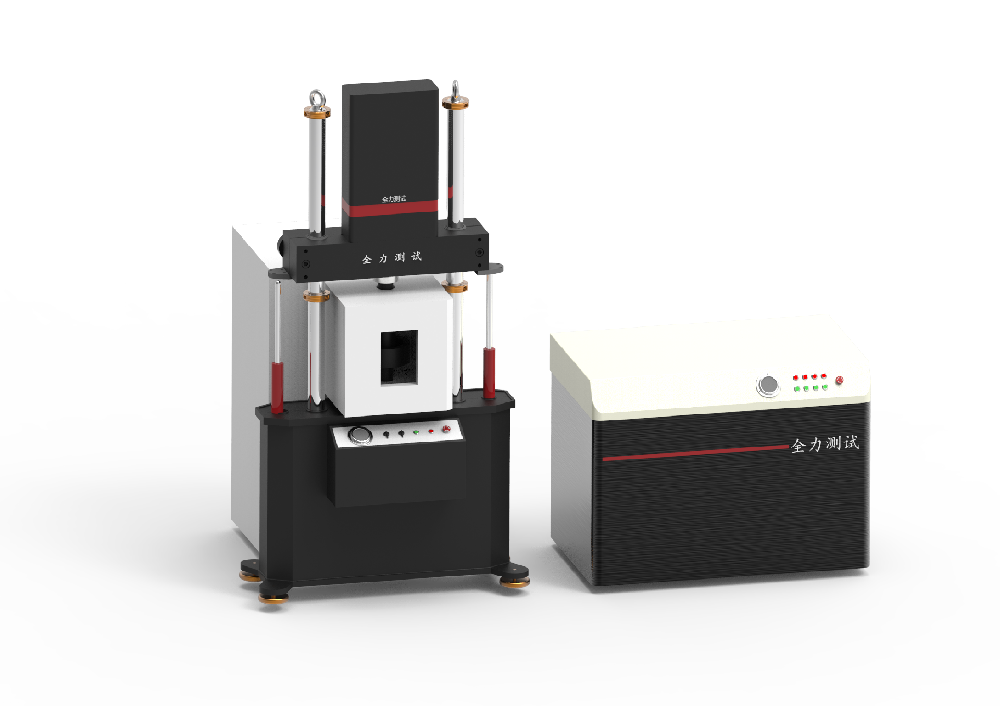

电子万能试验机:压力试验机的拉伸实验:拉伸实验(地应力-应变力实验)通常是将原材料试件两边各自夹在2个间距必须间距的工装夹具上,两工装夹具以必须的速率分离出来并拉申试件,测定试样上的应力变化,直到试样破坏为止。拉力机拉伸实验是科学研究材料力学抗压强度最普遍应用的方式 其一,必须应用恒速健身运动的。下边来为大家一下下压力试验机的安裝步骤及检修常见问题,我们一起来瞧瞧吧。

Tensile test of pressure testing machine: Tensile test (in-situ stress-strain force test) usually clamps the two sides of the raw material specimen on the fixture with two necessary spacing. The fixture separates the two fixtures at the necessary rate and stretches the specimen to determine the stress change on the specimen until the specimen is destroyed. Tensile experiment of tension machine is one of the most widely used ways to study the mechanical compressive strength of materials. Constant speed fitness exercise must be applied. Next, let's take a look at the installation steps and common problems of the downward pressure testing machine.

压力试验机的安裝步骤及检修常见问题一、压力试验机的安裝步骤压力试验机应安裝在清理、干躁、无振动且溫度适合的屋子里。压力试验机的服务器、油源箱的放置部位应依据试验仪外观图及路基图明确。基础的上平面应平整,用水平尺找平。待基础干燥后,再安装试验机。

Installation steps and common problems in overhaul of pressure testing machine 1. Installation steps of pressure testing machine Pressure testing machine should be installed in clean, dry, non-vibration room with suitable temperature. The locations of the servers and fuel tanks of the pressure testing machine should be defined according to the appearance and roadbed drawings of the tester. The upper plane of the foundation should be flat and leveled with a horizontal ruler. After the foundation is dried, the test machine is installed.

将试验机及油源分别搬运到混凝土的基础上,根据外型图及地基图,和油管尺寸确定主机和油源之间的距离和方向。

The distance and direction between the main engine and the oil source are determined according to the outline map, the base map and the size of the tubing.

然后用薄板垫入主机底部和基础之间。再用0.05/1000的方形水平仪进行找正,将方形水平仪放在油缸外表面上,在相互垂直的两个侧面找正其垂直度。其垂直度应不大0.2/1000。或将条式水平仪放在工作台,找正其水平度,水平度应不大于0.2/1000。

Then the thin plate is placed between the base and the base of the main engine. Then the square level instrument of 0.05/1000 is used to align. The square level instrument is placed on the outer surface of the cylinder and its perpendicularity is found on the two sides which are perpendicular to each other. Its perpendicularity should be less than 0.2/1000. Or put the bar level instrument on the workbench to find its level, which should be no more than 0.2/1000.

压力试验机找正后,用混凝土将底脚螺帽浇筑,将电动机轴下边的垫块垫牢。合用混凝土将电动机轴下边的间隙所有添充,维持电动机轴与混凝土基本的融合优良,避免在应用全过程因其受振动进而试验仪不水准。

After the pressure testing machine is aligned, the sole nuts are poured with concrete, and the pads under the motor shaft are firmly padded. The joint concrete fills up all the clearances under the motor shaft to maintain the basic fusion of the motor shaft and the concrete, avoiding the instrumentation of the tester due to its vibration during the whole application process.

地脚螺栓浇注后,在水泥未干燥前,不允许用地脚螺栓紧固试验机和开动主机(水泥干燥时间一般不少于10~15天),待水泥干燥后,用地脚螺栓将试验机固定在基础上。对压力试验机的安装精度进行复查,看是否与找正精度相符。如不符合,重新找正。

After grouting, it is not allowed to fasten the tester and start the main machine (the drying time of cement is not less than 10-15 days) before the cement is dried. After the cement is dried, the tester is fixed on the foundation with the foot bolt. Installation accuracy of the pressure testing machine is checked to see if it is consistent with the alignment accuracy. If not, correct again.

压力试验机的安装流程及维修注意事项二、压力试验机的维修注意事项1、从压力试验机上取出模块时,应注意记录其相对应的位置,连接的电缆号,对于固定安装的线路板,还应按前后取下相应的压接部件及螺钉作记录。

Installation process and maintenance precautions of pressure testing machine 2. Maintenance precautions of pressure testing machine 1. When removing modules from pressure testing machine, attention should be paid to recording their corresponding positions, connecting cable numbers, and for fixed circuit boards, the corresponding pressing parts and bolts should also be taken down before and after recording.

2、检修时电铬铁应放到随手的正前方,杜绝检修PCB线路板。烙铁头需作适度的整修,以融入集成电路芯片的电焊焊接,并防止电焊焊接时磕伤其他电子器件。

2. Electric ferrochrome should be placed in front of the hand during overhaul to prevent overhaul of PCB circuit boards. The soldering head needs to be properly repaired to incorporate into the welding of integrated circuit chips and to prevent other electronic devices from being damaged during welding.

3、线路板测量时应找到相应的焊点作为测试点,不要铲除焊膜,有的板子全部刷有绝缘层,则只有在焊点处用刀片刮开绝缘层。

3. When measuring PCB, the corresponding solder joints should be found as test points. Do not eradicate the solder film. Some boards are all brushed with insulating layer, and the insulating layer can only be scraped with blades at the solder joints.

4、测量线路间的阻值时,应断电源,测阻值时应红黑表笔互换测量两次,以阻值大的为参考值。

4. When measuring the resistance between lines, the power supply should be disconnected. When measuring the resistance, the red and black pens should be interchanged to measure twice, with the larger resistance as the reference value.

5、不应随意切断相关线路。压力试验机上的线路板大多是双面金属孔板或多层孔化板,印刷线路细而密,一旦切断不易焊接,且切线时易切断相邻的线。

5. Relevant lines should not be cut off at will. The PCBs on the pressure testing machine are mostly double-sided metal orifice plates or multi-layer orifice boards. The printed circuit is thin and dense. Once cut off, it is not easy to weld, and it is easy to cut off adjacent lines when tangent lines are cut off.

6、查清线路板的电源配置及种类,根据检查的需要,可分别供电或全部供电。应注意高压,有的线路板直接接入高压,或板内有高压发生器,需适当绝缘,操作时应特别注意。

6. Check the power supply configuration and types of PCB. According to the need of inspection, power supply can be provided separately or totally. Attention should be paid to high voltage, some circuit boards are directly connected to high voltage, or there are high voltage generators in the board, which should be properly insulated. Special attention should be paid to operation.

综上所述就是压力试验机的安装流程及维修注意事项的相关介绍,希望通过这篇文章能够对大家的所帮助。友情提示:如有不清楚的地方,请来电咨询。济南科盛试验设备有限公司是一家以研发、设计、生产、销售试验设备为主的现代化高科技公司。多种机器供您选择!

In summary, the above is the installation process of pressure testing machine and the related introduction of maintenance considerations. I hope this article can help you. Friendship Tips: If there is any unclear place, please call for consultation. Jinan Kesheng Test Equipment Co., Ltd. is a modern high-tech company which mainly focuses on R&D, design, production and sales of test equipment. A variety of machines for your choice!http://www.quanlitest.com